We all have a story of a bean bag exploding and filling a room with tiny white bean filling. And nobody wants to clean that up.

Buying a quality bean bag, means a durable product that can take the beating of children jumping on them. They won’t come apart at the seams. Won’t crack due to the sun, fade because of sun and will last for years either indoors or out.

In this post I explain what makes a quality bean bag and share some ‘insider information’ about how they are made.

What Makes a Quality Bean Bag?

Like all quality products It really comes down to the materials used.

Like a Rolls Royce is hand made using trusted materials and thread for their interiors.

Bean bags are a little different to all other types of furniture.

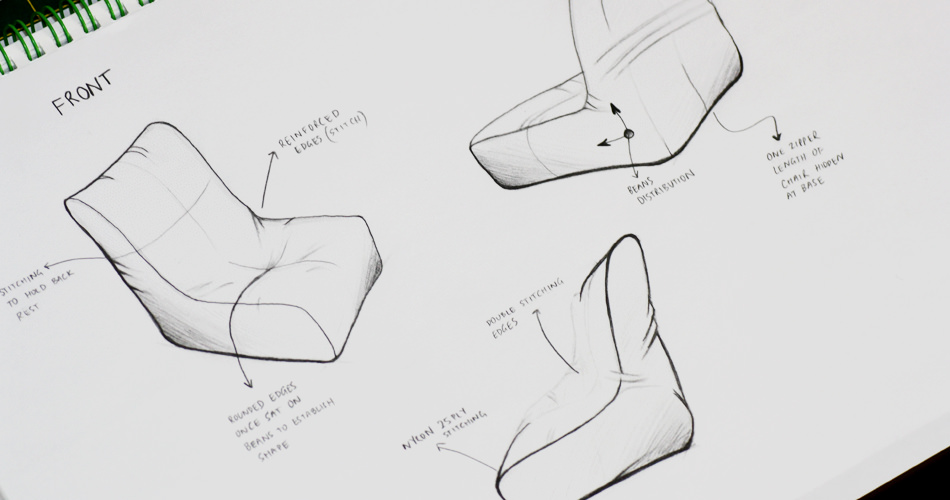

The main reason is how much pressure they take on their seam lines.

Common furniture is made of a frame and has a dense foam backing the top material sits on.

However, bean bags don’t have these same structures to dissipate pressures too.

And since the internal bean filling continually moves around, it means all the pressure of bean bags falls on the outer material upon.

All material has a “weak” point. The first point where it will split once a certain pressure is reached.

This weak point on all beans are the stitch lines of the fabric.

Since bean bags are sewn together these tiny holes placed in the fabric become this “weak point”.

And it doesn’t matter if your bean bag is made of the thickest vinyl or leather possible.

So, the quality comes down to how well they are held together once these stitch “holes” are created in the fabric.

The Thread

The tread is like the skeletal structure of a bean bag.

The thread needs to be sewn with a tight weave, and ideally be as strong as possible.

The thread we use at Bliss bean bags is a Nylon thread, a 25 Ply weave which is also used on the sails of huge ocean-going yachts.

It is strong enough to lift 200+kg, with a single thread.

When bean bags are double stitched, this creates a stronger seam line and creates an extra line of defence from them bursting.

Another common concern people have about bean bags is how well they do against the weather.

A lot of bean bags on the market are sold as outdoor bean bags and the fabric may very well be.

But, the thread used to bind the bean bag fabric pieces might not do well against the elements.

If the binding thread is not UV resistant and only the fabric is, a bean bag will eventually tear.

And it will likely happen at the weakest part (The stitch line)

That is another benefit of using Marine grade materials like the thread we craft our bean bags with.

They are designed to fight UV radiation, salt water and won’t degrade due to mould or mildew.

Durable bean bags

We always want a bean bag to be soft and still feel great after hours of sitting.

And I used to think that I couldn’t have a great feeling bean bag and it be durable as well.

The team here at Bliss have tested (and continue to test) various fabrics every year.

And the best fabric we have found to be comfy and robust is marine grade vinyl.

The bean bag above is over 5 years old and has never seen the indoors.

It has only lived outside, no cover, under 5 Aussie summers and winters, rain hail (literally) and shine.

We have tested other fabrics in this time, but they have “died” and are no longer with us.

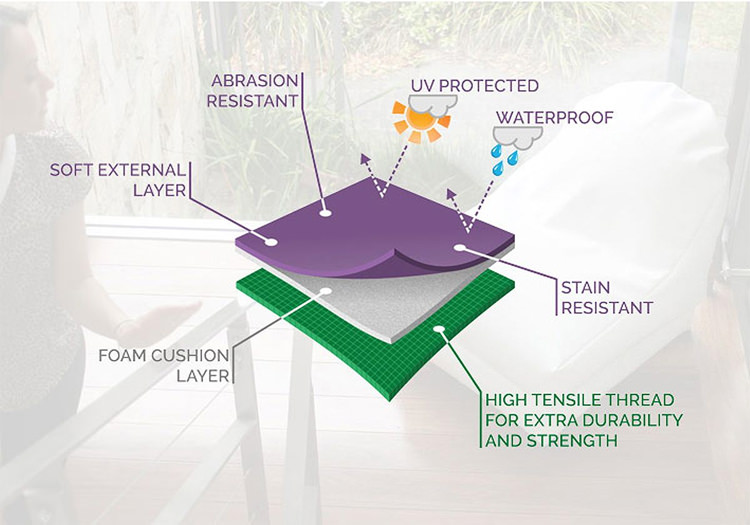

The reason that marine grade vinyl does so well, is because it is made of 3 layers of fabric in one.

The top layer is created with the colour embedded into it (it is not coated with a coloured dye or soaked with any colour pigmentation).

This means it won’t “come off”, or fade.

For that to happen the entire fabric would have to vanish, which isn’t possible.

The second layer is a very thin foam backing, this gives the fabric an extra piece of cushioning.

Making it feel soft and luxurious to sit in. (much like leather)

The last later is a polyester weave. And this “backing” of the bean bag material is the foundation for everything to rest on.

It gives the fabric strength in more than just one direction.

Meaning, you can pull, twist or bend the fabric and the backing always gives it the strength it needs.

It also provides another layer to hold the fabric too when the stitch lines are placed onto the fabric (as mentioned above).

Burst Proof Bean Bags

Some bean bags are sold as burst proof, in all honesty this is difficult to prove true for any manufacturer (including us).

The reason being; is that every bean bag is engineered to fail at some point.

That point might be at 1000kg+ but it is still a failure point.

We hand made the bean bags above for the City of Sydney at an outdoor exhibition.

And were designed to hold 10 people with room to spare, this means one ton can rest on these bean bag above without any concern.

At over 1500kg, I would be concerned about the structure and stitch lines at this point.

On a much smaller scale, we over-engineer our bean bags to ensure they don’t burst for certain weight ranges.

With the thousands of products we have sold over the years, we have not had a single report of a bean bag bursting.

Bean Bags and Inner Liners

You can’t wash our bean bags in a washing machine, as they are too thick and to heavy.

For instance, a popular design the “Grand Lounger” is close to 3kg (without any filling at all)

This means we don’t have an inner liner in our bean bags.

A few customers have expressed their concern about this, and rightfully so.

I have mentioned to them that during tests we did, the lining caused more of a nuisance to comfort when sitting in a bean bag.

The problem is the inner liner can be caught up, by twisting inside the bean bag.

Making the outer shell of the bean bag look a little strange.

And over time the bean bag completely changes shape. Not looking like a chair or tear drop for example, as it is designed to look.

Our way around this concern is to simply rid ourselves of this inner lining and secure the beans by a few measures of safety.

These include: hidden zippers, zippers with inbuilt locks and top stitched sew lines across the zipper itself.

Conclusion

When it comes to bean bags, quality trumps all.

Without a foundation of quality woven into the DNA of a bean bag, disaster will strike.

It might be a year or two away, but it will unfortunately cause a horrible mess in your home or outdoor setting.

We have found the materials used for the commercial marine industry serve bean bags best.

Especially when it comes to longevity and the ability to trust in how durable they will be with children jumping on them.

Bean bags take a lot more pressure than traditional furniture, since they don’t have a firm (solid) backing.

This nature of bean bags needs to be considered before beginning to design any new shape

And any new design needs to be tested thoroughly in every way possible.

After this we then share our new designs for the world to enjoy.

If you have any questions about good quality bean bags or how you can maintain them for life please let me know.

We are happy to help in any way we can.